At the very core of any Internal Combustion Engine, whether gasoline-powered spark-ignition or diesel-powered compression-ignition, lies the efficient and punctual combustion of a precisely metered air-fuel mixture.

Now while this may sound quite straightforward, the variables under which the engine operates have a significant impact on how and when the fuel is delivered. For instance, as ambient temperature increases air density drops, therefore, to maintain the stoichiometric mixture required for complete combustion of the fuel the amount has to be reduced to maintain the correct volumetric ratio of air to fuel. For a gasoline engine, this is roughly about 14.7 parts of air to one part of gasoline (expressed as Lambda 1 in closed-loop engine management systems).

Similarly, under wide-open throttle and high load conditions, the engine requires more fuel than the stoichiometric-ideal mixture to produce maximum power. Under these conditions, the mixture is enriched to about 12.5:1.

Consequently, as illustrated by these everyday examples, optimizing the air-fuel mixture for the widely varying conditions under which the engine operates is not always easy.

In this article we will explore the various gasoline fuel-delivery systems and technologies Porsche has used over time, to not only produce power but do this economically and environmentally friendly. We will follow the development of these systems from the carburettors fitted to early Porsche 901/911s in the 1960s to the introduction of electronic fuel injection in the 1970s.

Why Porsche Ditched The Carburettor On The 911

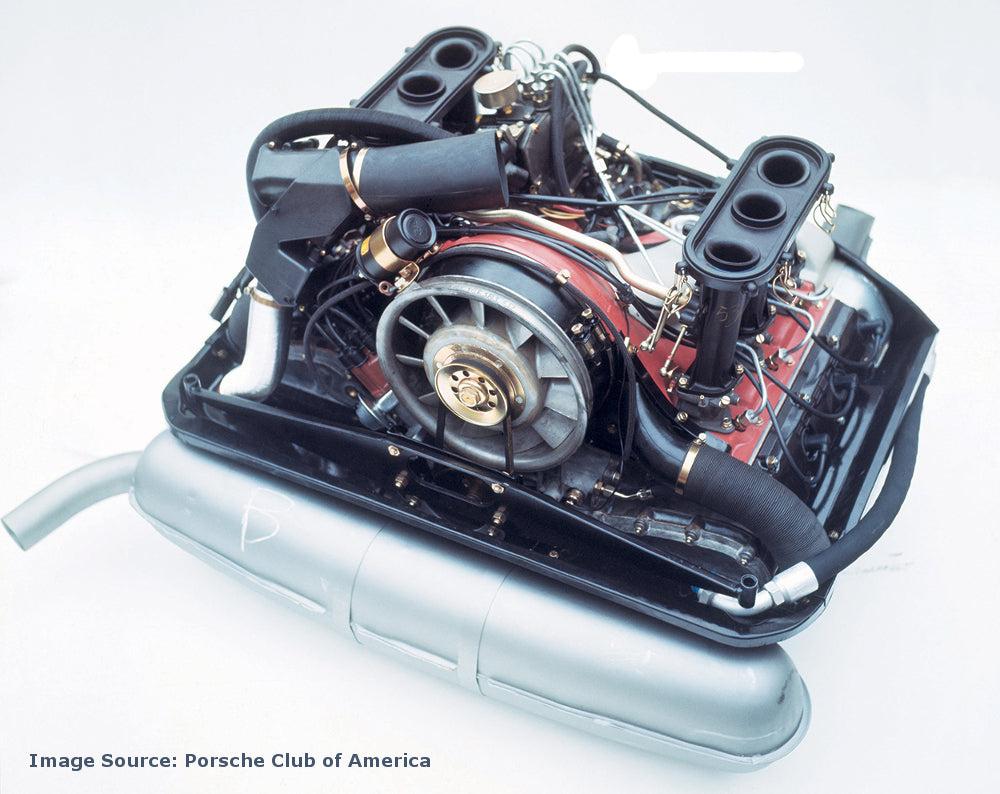

For the production version of the 901 (later renamed 911), Porsche developed the type 821 six-cylinder engine using Solex carburetors. These Solexes were specifically adapted for the type 901/911 engine as the Solex type 40PI, with three being mounted on a common intake manifold with a single, integral fuel float bowl per bank of cylinders.

Although 911 Porsches were fitted with Solexes from the start of production in 1964, due to their short service-life and associated tuning issues less than 2000 cars were built with Solex carburetors and Pierburg fuel pumps. The Solexes were finally replaced by Weber 40IDA3C carburetors in Feb 1966.

However, although the Weber carburetors were capable of delivering excellent fuel mixtures across a wide range of engine operating conditions they were still limited by the mechanical/ (vacuum) fluid dynamics of the design. Thus, although the ‘main circuit’ of the Weber delivered mixture control and power comparable to an injection system, the intermediate circuits – such as idle, off-idle, and mixture control up to ¾ throttle-opening – fell far short of the control mechanical fuel injection (MFI) provided. The other limitation of carburetion was that relying on a vacuum, atomization of the fuel droplets was not as good, often resulting in ‘hot-spots’ or ‘lean zones’.

So, to comply with the tightening emissions regulations and improve the performance of the 911, Zuffenhausen turned to MFI on its iconic rear-engined sports car, replacing carburetors with MFI systems on certain models in 1972, with standard fitment taking place from 1974.

Porsche Turns To Mechanical Fuel Injection

Originally introduced on the 906 sports racer, the mechanical fuel injection system developed by Kugelfischer and later built by Bosch was subsequently fitted to the 911R before making its road-going debut on the 2.0-liter Porsche 911S.

Built in an age before electronic sensors, the heart of the system was the fuel pump that was operated by a camshaft with a series of mechanical ‘sensors’ creating an ever-changing fuel delivery map based on throttle position, engine speed, and barometric pressure.

To regulate the amount of fuel to match the throttle position, a pull rod on the throttle linkage adjusted a 3D ‘space cam’ housed in the bottom of the pump. The irregular profile of this cam was shaped to match the fuel-delivery map on each 911 variant - differing for ‘E’, ‘S’ and ‘RS’ models.

On top of this a centrifugal governor, connected to the camshaft, helped to regulate the overall fuel flow through the pump to suit the engine speed, while a solenoid valve provided automatic cold-start enrichment, doing away with the need for a manual choke.

Over and above accurately metering the fuel across a wide range of operating conditions, the increased injection pressure of between 225 and 250psi (15.5 and 17 Bar) ensured greater atomization of the fuel. This resulted in a more even flame front during ignition, contributing to more efficient combustion.

Porsche replaced the MFI with Bosch’s more emissions-friendly K-Jetronic Continuous Injection System (CIS) starting in 1973. Although still a mechanical injection system, it differed from the original MFI in that it measured the amount of air coming into the engine to determine how much fuel should be injected into each of the engine intake ports, delivering this simultaneously (continuously). Although the operating pressure of 80psi (5.5 Bar) was lower than that of the MFI it still allowed for adequate atomization.

The continuous nature of the system – injecting fuel to all cylinders simultaneously - meant that some of the fuel would always remain in the intake port until the intake valve opened. While this would seem less than ideal, there was always some atomized fuel going into the cylinder, and K-Jetronic CIS-equipped engines had a special piston crown designed to generate a tumbling effect to help the mixing of the air and fuel.

The CIS was introduced on built between 1973 and 1983, the 924 manufactured from 1977 to 1985, the 928 between 1977 and 1983, and 911 Turbos from 1977 to 1994. From a service point of view, the system was quite straightforward - there were only two main adjustments: idle-speed and mixture.

While these mechanical injection systems were a quantum leap forward in fuel delivery, it wasn’t until electronics entered the arena that the demands placed on the fuel system were comprehensively addressed.

The Progress In Electronics Heralds Porsche’s First Electronic Fuel Injection

Bosch’s early electronic port fuel injection systems as used by Porsche relied on fuel injectors activated by electromagnetic solenoids. The injectors were fed a constant supply of pressurized fuel, at about 29 to 37psi (2.0 to 2.5 bar), via a common fuel rail for each bank of cylinders. A fuel pressure regulator that restricted the return line to the fuel tank maintained a constant pressure. While the fuel atomization capabilities of these early EFI systems were not as good as their mechanical predecessors, they made up for this with precise fuel metering across a wide range of operating conditions.

The four-cylinder 914 was Porsche’s first application of electronic fuel injection, although Porsche had actually briefly considered Bosch’s D-Jetronic (the “D” stood for “druck” – pressure in German) for use in the 911. The K-Jetronic MFI, however, proved to be better suited to the high-revving 911 engine.

Nevertheless, the D-Jetronic system was more than adequate for the low-revving, linear nature of the Volkswagen Type IV engine fitted to the 914. The 914’s fuel-injected flat-four used a single throttle body that fed air into a central intake manifold plenum, with individual intake runners to each intake port; the fuel injectors were mounted between the fuel rails and intake ports.

To accurately determine how much fuel to inject into the engine under any given engine operating condition, the D-Jet ECU relied on a speed/density model to estimate airflow into the engine. This calculation was made, based on analog inputs from an intake manifold pressure sensor containing an element that was exposed to the atmosphere to compensate for varying altitudes, and a throttle position sensor. A pair of trigger points at the base of the ignition distributor shaft determined engine rpm, whilst an intake air-temperature sensor was used to derive the air density. For cold starting, a cylinder head temperature sensor determined when to enrich the mixture.

The quantity of fuel injected into each cylinder was controlled by varying the amount of injector open time. Typical fuel injector pulse widths varied between 1.5-2.0 milliseconds to over 20 ms at higher engine speeds and loads.

The D-Jet ECU that processed all the inputs was best described as an analog computer with no digital processing capabilities. The ECU also lacked the sensing hardware to provide sequential fuel injection, so the injectors were activated simultaneously in pairs. As with CIS injection, any fuel injected against a closed intake valve would remain in the port until the valve opened to draw in the air/fuel charge.

Although D-Jetronic worked quite well in the 1.7 and 2.0-liter 914 applications, the pressure sensor and distributor-mounted injector trigger contacts proved to be prone to mechanical wear and subsequent inaccuracy, and the limitations of its basic ECU precluded the system’s use in high-performance applications like the 911.

To improve fuel delivery, Bosch’s updated L-Jetronic EFI system, fitted to the 1.8-liter 914 built between 1974 and 1976 used a vane-type airflow meter to directly measure the quantity (but not the mass) of the air entering the engine. Located upstream of the throttle body, the airflow meter used a spring-loaded vane that varied the resistance measured by an electrical ‘wiper track’ to adjust the fuel injector pulse-width to suit the engine’s demands.

The direct measurement of airflow offered a more accurate measurement of the engine’s requirements than the earlier D-Jet system, and also compensated for engine wear or other changes in airflow such as incorrectly set valve clearances.

The more sophisticated L-Jet ECU measured engine rpm from the primary side of the ignition circuit. Other advances included an intake air temperature sensor integrated into the airflow meter housing and an auxiliary air regulator (controlled by a simple thermo-time switch and not the ECU) that provided a fast idle after a cold start.

Following ten years of continuous improvement in fuel-metering and delivery Porsche had developed a system capable of accurately delivering fuel under almost any operating and climatic condition - but two challenges remained before EFI would make an appearance on the 911: Improving fuel-atomization and integrating the system that delivers the spark to ignite the fuel-mixture.

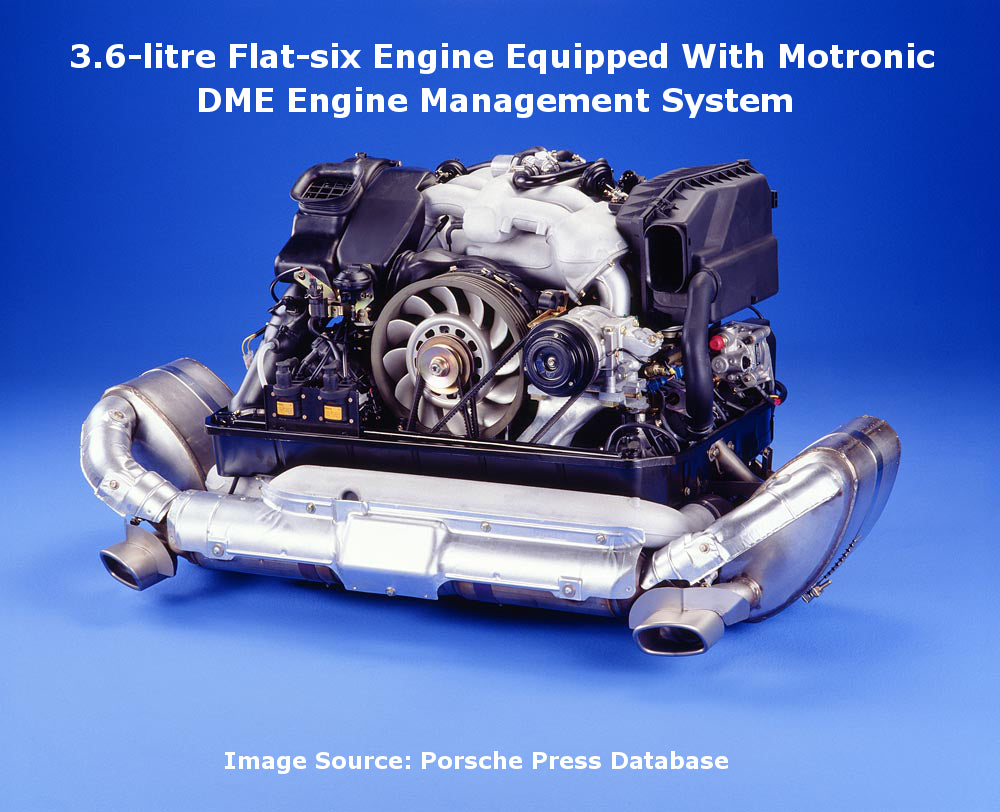

In a follow-up article we’ll take a look at Porsche’s Motronic fully electronic engine management system, first fitted to the 911 in 1984, and the subsequent adoption of direct fuel injection.

Did you enjoy this article? Avoid missing future publications by subscribing to this blog's RSS feed using

https://frazerpart.com/blogs/technical-articles.atom